Links:https://www.bachrc.de/ceramic.html?language=en

晶圓加熱器: 可以製造由氮化矽製成的陶瓷熱板,外徑為400mm。 在這個直徑內,任何矩形,定制的形狀和開口是可能的。 板的典型高度為5mm,集成冷卻通道約為15mm。 陶瓷材料的特殊性能和質量低,允許加熱速度快,溫度分佈均勻,控制精度高。 與金屬相比,即使在溫度快速變化的情況下,陶瓷的表面由於其低熱膨脹而保持平坦。 熱壓氮化矽的高強度保證了高抗應力(例如高壓負荷)和優異的耐磨性。 熱板非常適合半導體加工系統中的苛刻工藝。

晶圓加熱器: 我們的內部設計在尺寸,配置或性能方面進行了任何修改,簡單方便。 可以在設計中添加用於溫度傳感器的安裝支架孔和孔。 也可以添加激光切割真空槽。 我們的熱板已經平坦,但是它們可以進一步研磨至<10μm的平坦度以滿足特定要求。 此外,我們的陶瓷加熱導體具有定制設計,可以集成幾個加熱區。 用於補償熱損失的設備和用於溫度測量的內部測試引線可以輕鬆構建。為了在高達1000°C的高真空度下工作,可以提供引腳觸點。 在幾個客戶項目中,我們集成了一個可由具有集成通道的冷卻模塊生產的冷卻功能。 該冷卻模塊對加熱器進行釬焊高真空密封。 冷卻通過壓縮空氣或氮氣進行。

晶圓加熱器 myBlossom® Ceramic Wafer Heaters

陶瓷晶圓加熱器 Ceramic Wafer Heaters

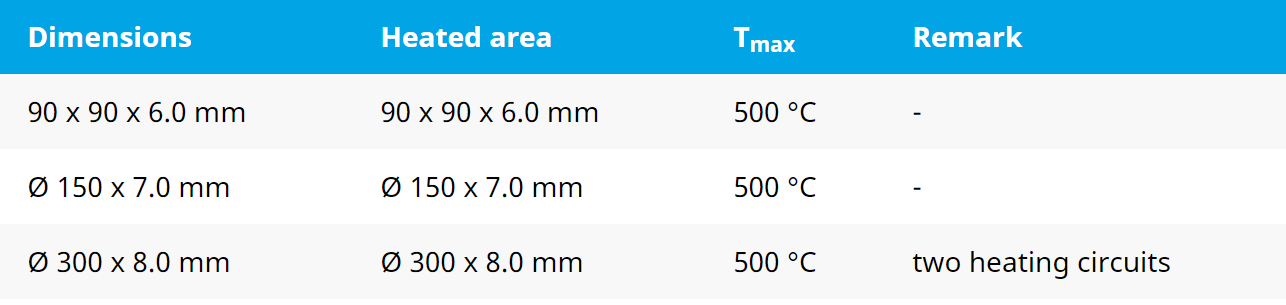

標準陶瓷晶圓加熱器 Standard Ceramic Wafer Heaters

半導體陶瓷晶圓加熱器 Semiconductor Ceramic Wafer Heaters

陶瓷加熱器 Ceramic Heating Elements 陶瓷加熱元件

氮化矽陶瓷加熱器 Silicon Nitride Ceramic Heating Elements

自華光電 - 德國Bach-RC陶瓷加熱器 台灣獨家代理商。

Allen K. Lin | Allen@myblossom.tw | LINE ID: Allen-007 | Wechat ID: Allen-006 | T: 0910-782775

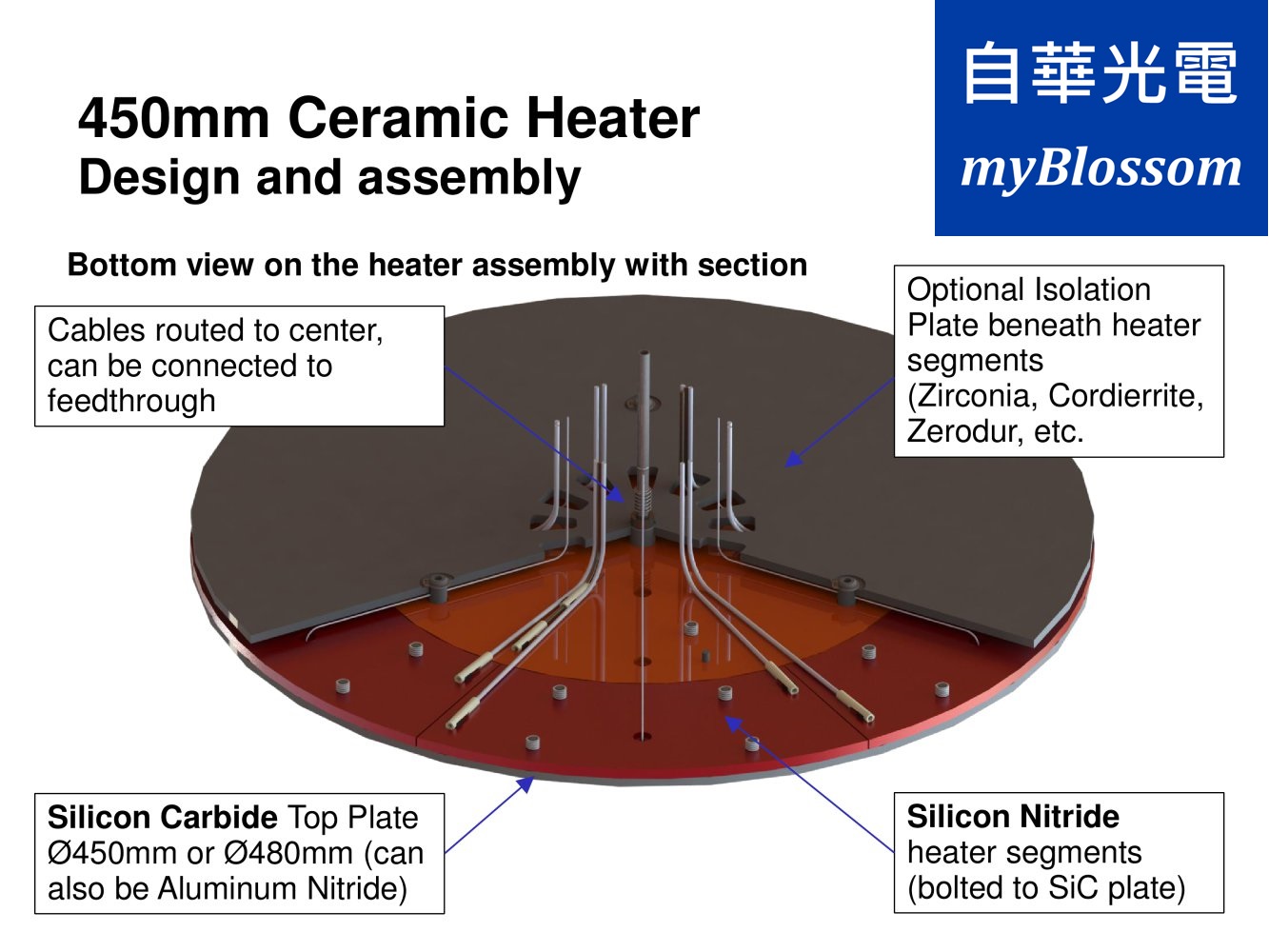

Wafer heaters

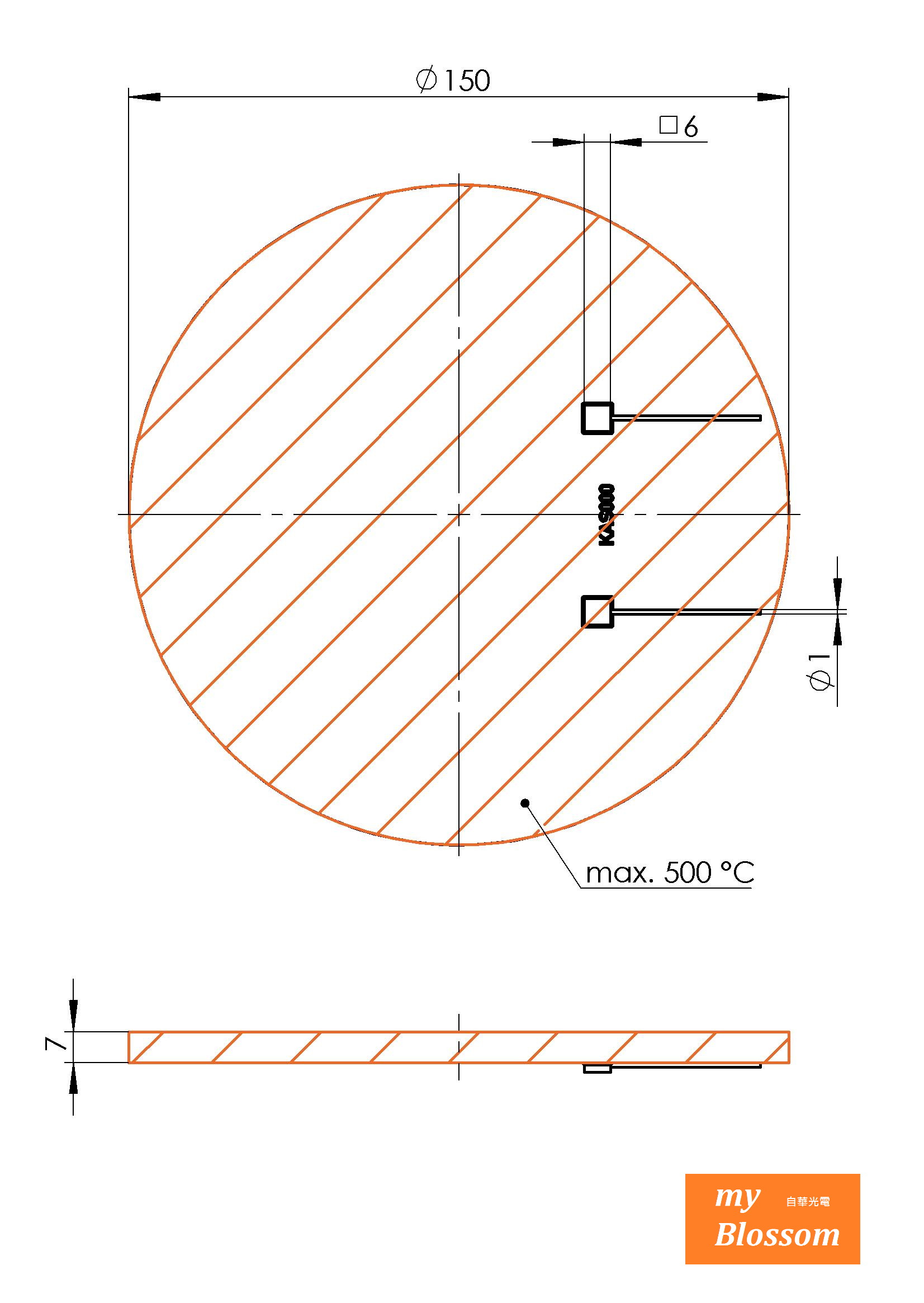

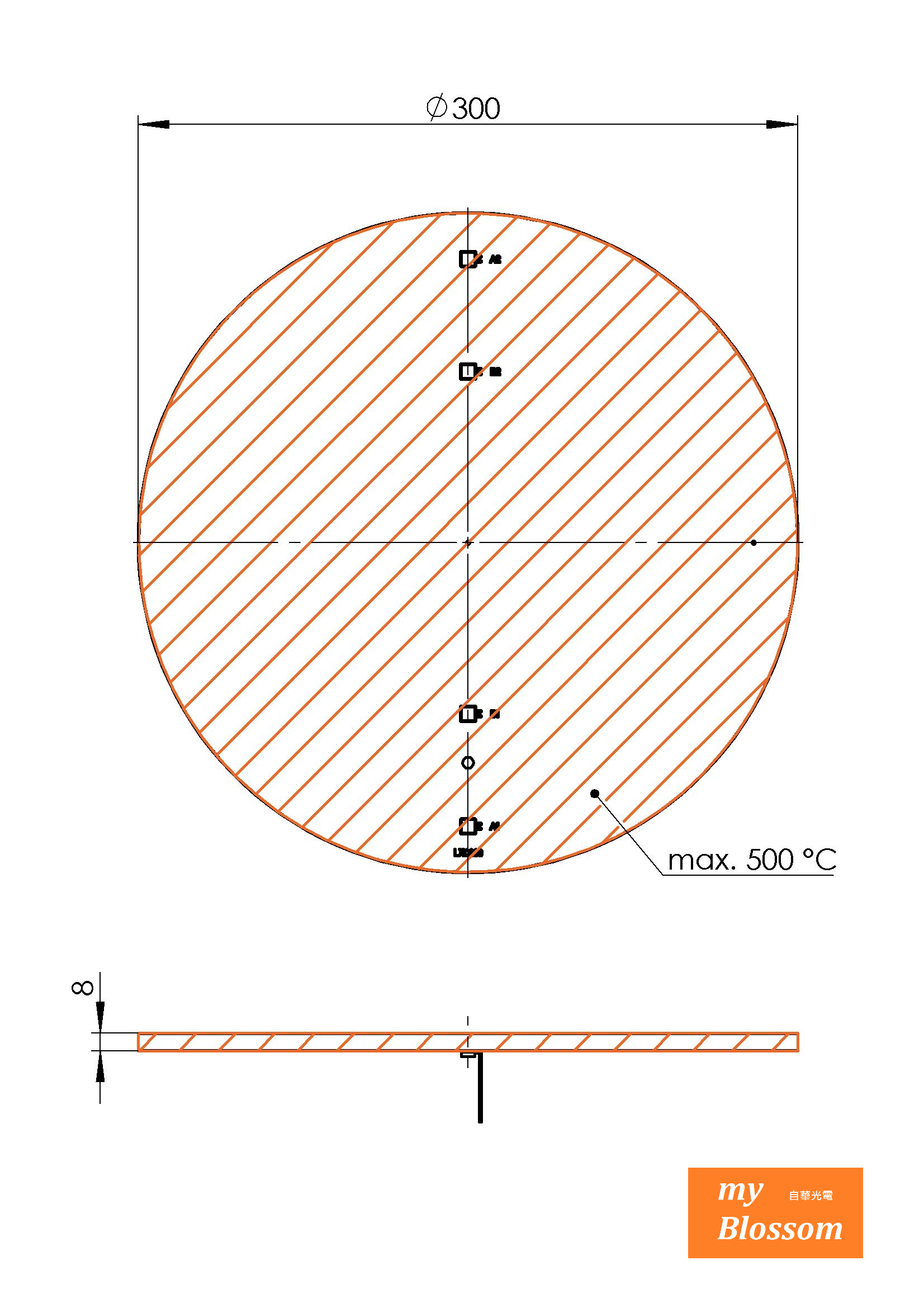

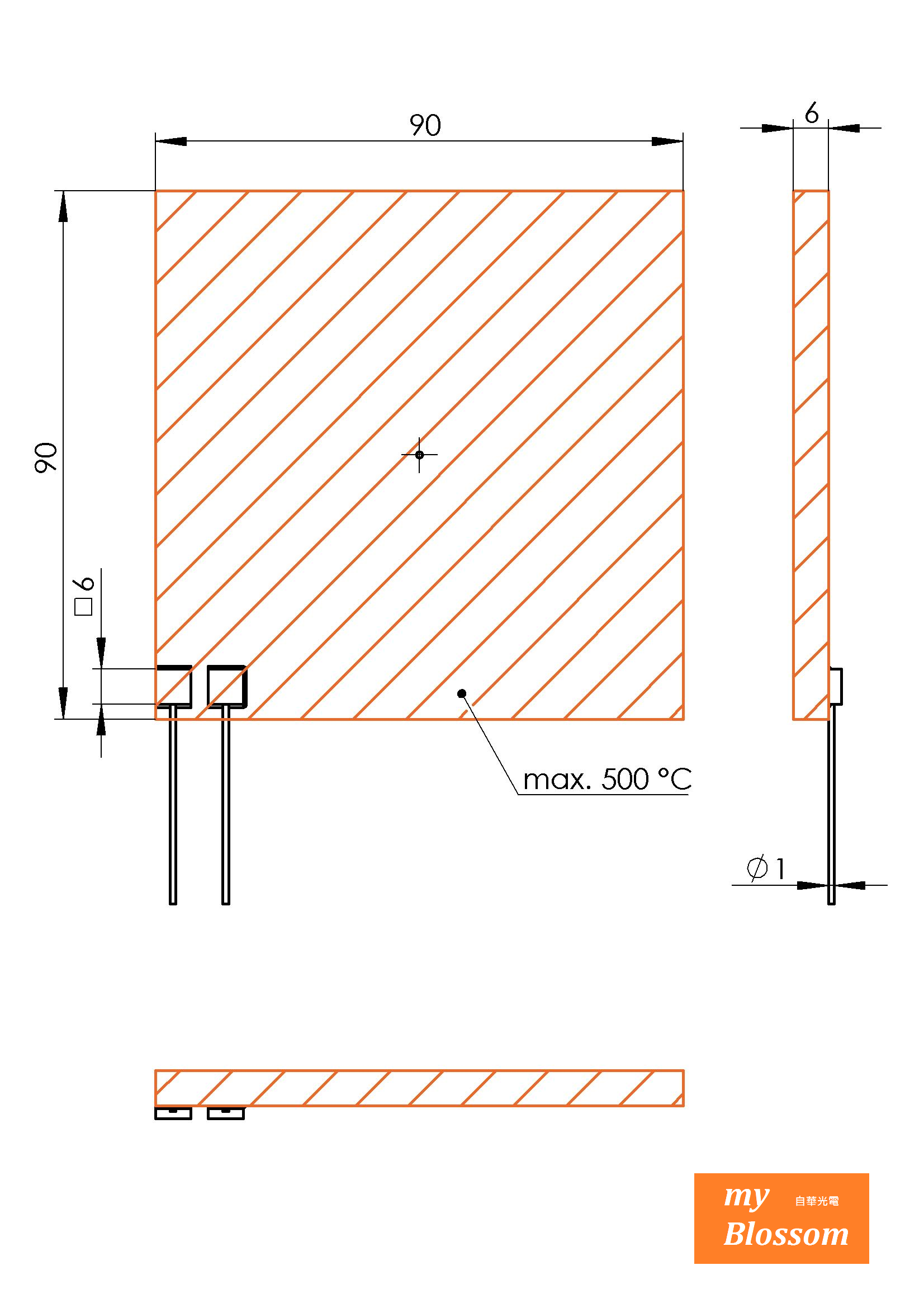

Ceramic hot plates made of silicon nitride can be produced with an outer diameter of 400 mm. Within this diameter any rectangular shapes, customized shapes and openings are possible. A typical height of the plates is 5 mm and with an integrated cooling channel about 15 mm. The special properties and low mass of the ceramic material allow fast heating rates, uniform temperature distribution and outstanding precision in control. In comparison to metal the surface of ceramic stays flat due to its low thermal expansion even when operated with fast changes in temperature. The high strength of hot-pressed silicon nitride guarantees high stress resistance (e. g. with high pressure loads) and excellent wear resistance. The hot plates are very suitable for demanding processes in semiconductor processing systems.

Ceramic hot plates made of silicon nitride can be produced with an outer diameter of 400 mm. Within this diameter any rectangular shapes, customized shapes and openings are possible. A typical height of the plates is 5 mm and with an integrated cooling channel about 15 mm. The special properties and low mass of the ceramic material allow fast heating rates, uniform temperature distribution and outstanding precision in control. In comparison to metal the surface of ceramic stays flat due to its low thermal expansion even when operated with fast changes in temperature. The high strength of hot-pressed silicon nitride guarantees high stress resistance (e. g. with high pressure loads) and excellent wear resistance. The hot plates are very suitable for demanding processes in semiconductor processing systems.

Our in-house designs make any modification in size, configuration, or performance simple and convenient. Mounting-bracket holes and bores for temperature sensors can be added to the design. Laser-cut vacuum grooves can be added as well. Our hot plates come already flat ground, however they can be ground further up to a flatness of < 10 μm to meet specific requirements. Furthermore, our ceramic heating conductor with its customized design allows the integration of several heating zones. Devices to compensate for heat loss and an internal test lead for temperature measurement can be easily built in. For operating in high vacuum at up to 1 000 °C a pin contact can be supplied. In several customer projects we integrated a cooling function which can be produced by a cooling module with integrated channels. This cooling module is brazed high vacuum tight to the heater. Cooling is effected by compressed air or nitrogen.