自華光電®精密工具 | myBlossom® Tools

自華光電®代理 提供在後端和前端半導體市場全面的解決方案,以滿足客戶對微電子行業用於所有主要封裝流程的高精度消耗工具不斷增長的需求,以及用於晶片或導電薄膜電阻率測試的探頭解決方案。

進一步確立了自己的地位,成為醫療,航空航天和軍事行業標準和定制的高精度工具和零件的領先供應商。 擁有復雜而獨特的製造設備,再加上獲得專利的鍍膜技術,可提供具有最低擁有成本的高質量解決方案,從而使客戶能夠迅速滿足其行業的苛刻需求。 以其靈活的工程和製造環境而自豪,該環境可促進響應速度和較短的上市時間,而不會影響質量。我們的專業工程師可以討論由多種高級金屬,塑料和陶瓷製成的具有復雜幾何形狀和嚴格公差的零件的設計和工藝的優化。

進一步確立了自己的地位,成為醫療,航空航天和軍事行業標準和定制的高精度工具和零件的領先供應商。 擁有復雜而獨特的製造設備,再加上獲得專利的鍍膜技術,可提供具有最低擁有成本的高質量解決方案,從而使客戶能夠迅速滿足其行業的苛刻需求。 以其靈活的工程和製造環境而自豪,該環境可促進響應速度和較短的上市時間,而不會影響質量。我們的專業工程師可以討論由多種高級金屬,塑料和陶瓷製成的具有復雜幾何形狀和嚴格公差的零件的設計和工藝的優化。

myBlossom was founded in 2016. Since then, We have established itself as a global leader in the semiconductor marketplace, in both the back and front end. We offer comprehensive solutions to meet our customer's growing demands for high-precision expendable tools for the micro-electronics industry for all major packaging processes as well as Probe Heads solutions for wafers or thin conductive films resistivity tests. myBlossom is also a world leader the manual wire bonders industry with our state-of-the-art products and support.

We have further established itself as a leading supplier of standard and customized high-precision tools and parts for the Medical, Aerospace and Military Industries. With sophisticated and unique manufacturing equipment, along with patented coating technologies, We provide high-quality solutions with the best cost of ownership, allowing customers to rapidly meet the demanding needs of their industry. We take pride in its flexible engineering and manufacturing environment, which facilitate responsiveness and short time to market without compromising quality. Our professional engineers are available to discuss optimization of design and process of parts with complex geometry and tight tolerances, manufactured from a variety of advanced metals, plastics and ceramics.

自華光電®精密工具

Allen K. Lin | Allen@myblossom.tw | LINE ID: Allen-007 | Wechat ID: Allen-006 | T: 0910-782775

歡迎 SPT, K&S, Gaiser, Adamant, Peco, Metgas, DouYee & Kosma 轉換成 myBlossom®。

Micro Point Pro Ltd. (MPP)

Small Precision Tools Inc. (SPT) 小精密工具有限公司

Kulicke & Soffa Industries, Inc. (K&S) 庫力索法股份有限公司

Adamant Namiki Precision Jewel Co., Ltd. 丹特科技有限公司 代理

Peco Co., Ltd. 沛科半導體科技有限公司

Megtas Co., Ltd. 長洛國際股份有限公司 代理

Dou Yee Technologies Pte., Ltd. (DYT)

Korea Semiconductor Material Co., Ltd. (Kosma)

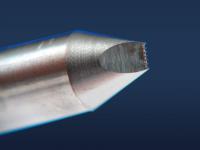

自華光電®鋁線楔焊工具 myBlossom® Wedge Bonding Tools

自華光電®鋁線鍵合劈刀/鋁線楔焊工具/鋁線楔型焊接工具

傳統劈刀鍵合工藝,作為優先選擇的工藝而被廣泛應用到鋁線鍵合的各種領域。如今,它正逐漸成為內部接合中可選擇的工藝方式,例如:卷帶自動鍵合、倒裝晶片及其它應用領域。劈刀鍵合技術仍然是鋁絲鍵合工藝應用領域中的一種選擇。

採用各種不同的硬質合金材料開發&製造出各類不同型號的劈刀鍵合工具,其中,由碳化鎢材料製成的工具成為鋁絲應用領域的首選材料,然而,鈦合金工具則適用于金線劈刀鍵合工藝。

myBlossom® WEDGE BONDING TOOLS

Traditionally Wedge Bonding was used as the preferred process for wire bonding applications that use aluminum wire. Today, it is becoming the process of choice for interconnect methods such TAB, FLIP Chip and others.Wedge Bonding remains the choice for Wire Bonding process and applications that use aluminum wire.

We develops and manufactures a broad range of Wedge Bonding tools from a variety of carbide materials. The most popular tungsten carbide tools are used for aluminum wire applications while titanium carbide tools are suitable for gold wire Wedge Bonding.

傳統劈刀鍵合工藝,作為優先選擇的工藝而被廣泛應用到鋁線鍵合的各種領域。如今,它正逐漸成為內部接合中可選擇的工藝方式,例如:卷帶自動鍵合、倒裝晶片及其它應用領域。劈刀鍵合技術仍然是鋁絲鍵合工藝應用領域中的一種選擇。

採用各種不同的硬質合金材料開發&製造出各類不同型號的劈刀鍵合工具,其中,由碳化鎢材料製成的工具成為鋁絲應用領域的首選材料,然而,鈦合金工具則適用于金線劈刀鍵合工藝。

myBlossom® WEDGE BONDING TOOLS

Traditionally Wedge Bonding was used as the preferred process for wire bonding applications that use aluminum wire. Today, it is becoming the process of choice for interconnect methods such TAB, FLIP Chip and others.Wedge Bonding remains the choice for Wire Bonding process and applications that use aluminum wire.

We develops and manufactures a broad range of Wedge Bonding tools from a variety of carbide materials. The most popular tungsten carbide tools are used for aluminum wire applications while titanium carbide tools are suitable for gold wire Wedge Bonding.

自華光電®黏晶工具/固晶工具 myBlossom® Die Bonding Tools

自華光電® 晶片鍵合劈刀/黏晶工具/固晶工具/焊晶工具

晶片鍵合過程發生在鋁線鍵合之前。將選定的晶片進行封裝,封裝時採用共晶或粘芯固晶方法進行機械連接。晶片夾腳應用在晶片需要高精密定位的過程中:在晶片和粘合工具之間保持最小接觸面,使其具有很強的握力--特別是在共晶晶片鍵合過程中得到應用。

扁平吸嘴用於熱壓或銀漿固晶過程中的拾起、轉移、放置晶片到焊盤的工具。可提供各種不同材料製成的真空吸嘴。它們可用於各種不同領域。採用特別定制且擁有獨一無二裝配過程。 它們可適用於全部普通晶片鍵合機器型號。

myBlossom® DIE BONDING TOOLS

The Die Bonding process takes place prior to wire bonding. The selected die is placed in a package and mechanically connected using either eutectic or adhesive die attach methods.Die collets are used when the process requires high accuracy for the positioning of the die. They allow for minimal contact between the die and the attachment tool and provide a strong grip, especially in the eutectic die bonding.

The Flat Face Pick Up tool is used in a Thermo-compression or Epoxy Die Attach process for picking up, holding, transferring and placing a die on the substrate.Micro Point Pro offers a wide selection of Vacuum Pick Up tools for various applications, manufactured from a wide range of materials and custom designed for your unique assembly process. Our tools are suitable for use with all common die bonding machine models.

自華光電®液體點膠頭 myBlossom® Fluid Dispensing Tools

自華光電®液體點膠頭

設計並生產固晶工藝中所使用的各類點膠頭和壓焊工具,這些工具都可以根據客戶的應用要求進行量身定做,並由金屬,陶瓷等各類基材可供選擇,MPP銀漿點膠噴嘴設計可防止出現不連續的銀漿,例如:拖尾、橋接、空隙及銀漿覆蓋不足等現象。

常用點膠頭類型如下:燒錄噴筆、噴頭/多頂針噴嘴、V型溝槽/U型溝槽噴嘴。點膠頭設計用於歐洲半導體設備公司、動態穩定系統或任何其它黏芯機器。在許多情況下,使用特製的,可調整的適配器是必不可少的,MPP已開發出一種特殊的製造過程,該過程可確保適配器具有較高精確度,因而,它可防止漏液,順利完成點膠過程。

myBlossom® FLUID DISPENSING TOOLS

Excels in the design and manufacture of various types of dispensing nozzles for customized applications. Our dispensing nozzles are designed for accurate dispensing of the glue onto the substrate which helps to prevent inconsistent epoxy problems like tailing, bridging, voids and insufficient epoxy coverage. This enables our customers to achieve superior dispensing performance. The complete set of nozzles and adaptors is available for all types of bonders in the market.

The common tool designs are: Writer Nozzle Pen、Shower Head / Multi-Needle Nozzle、V-Groove / U-Groove Nozzle Shape. The dispensing tools can be designed for ESEC, ASM or any other Die-Attach machine. In many cases, it is essential to use customized and adjustable adaptors. MPP has developed a manufacturing process that ensures that its adaptors are accurate, thus preventing leakage and allowing for a smooth dispensing process.

自華光電®四點探針 myBlossom® Four Points Probe

自華光電®四點探針/晶圓電阻率測量四點探針/薄膜電阻率測量四點探針 myBlossom® 4 Points Probe

四點探針/四點探頭的領先供應商,可用於晶圓電阻率以及導電薄膜的加工製造。我們的探頭在全球已使用多年,可用于最負盛名的晶圓電阻率測量設備上。我們可製造一整套複雜探頭元件(主體,佈線和針),可用于定制的高精密設備上。經過多年經驗的積累,我們的專業技術人員可裝配出高精度的優質探頭,用於滿足市場上的短期交付使用要求。

頂針之間的間隙範圍可達到:0.635mm--1.591 mm(緊密度容限:+/-0.005mm)。頂針壓力範圍在:50g --200g(緊密度容限:+/-1g)。根據需求,我們只提供頂針,我們的頂針在市場上屬於優質頂針,它的超細拋光頂針的頂部半徑可從0.025mm -- 0.635mm。針尖半徑尺寸範圍:0.025mm--0.635mm。

薄膜電阻具有均勻厚度薄膜電阻的量度。通常被用作評估半導體摻雜的結果。這種工藝的例子有:半導體的摻雜領域(比如矽或者多晶矽),以及被絲網印刷到薄膜混合微電路基底上的電阻。薄膜電阻的概念與電阻或者電阻率相對,可直接用四端點測量技術測量法(也稱為四點探針測量法)或范德堡法來測量。

四點探針是使用來減少接觸電阻的問題,它常被使用來確認材料的片電阻值。感應測量也是有被使用。此方法是測量由渦流產生的屏蔽效果。這種技術的其中一種是被測導電片放置在兩個線圈之間。另外,這種非接觸式片電阻值的測量方法也可以測量封裝內的薄膜或表面粗糙度大的薄膜。

myBlossom® FOUR POINTS PROBE

A leading supplier of Four Point Probe heads for measurement of resistivity on wafers and on thin conductive films. Our probe heads have been used for many years all over the world on the most well-known wafer resistivity measuring equipment. We manufacture complete and complex probe head assemblies (body, wiring and needles) on high precision customized equipment. With years of experience, our expert technicians assemble high accuracy best-in-class quality probe heads. Flexible production schedules allow for short lead time.

Spacing between needles is available from 0.635mm to 1.591 mm (with tight tolerance: +/-0.005mm). Needle pressure is available from 50g to 200g (with a tight tolerance of +/-1g). Upon request, we supply needles only. Our needles known for their excellent quality and very fine polishing. Needle tip radius varies from 0.025mm to 0.635mm.

自華光電®特製的微電子工具 myBlossom® Customized Tools

自華光電®特製的微電子工具

在半導體及微電子裝配業所使用的定制工具和鋁線鍵合領域擁有淵博的技術製造經驗。MPP擁有深厚的專門技能,可設計並製造表面貼裝技術工具,實施球焊工藝和其它各種輔助部件,例如:指形壓板,它用於粗線鍵合工藝、夾緊部件、加工部件和液體點膠頭適配器;

與半導體行業的領先企業通力合作,可為領先的原始設備製造商,提供精密工具和其他部件,領先原始設備製造商,可將它們用於批量生產以及生產同一時期的新一代各種機器的原始工具。

myBlossom® CUSTOMIZED TOOLS

Has extensive in-depth experience in wire bonding and in custom tools for the semiconductor and microelectronic assembly industries. We have the know-how and capability to design and manufacture Surface Mount Technology tools, ball soldering and other accessories such as finger clamps for Heavy wire bonding process, clamping and p-parts, and special adaptors for liquid dispensers.

Collaborates with leading companies in the semiconductor industry and provides precision tools and customized parts to leading OEMs for mass production as well as prototyping tools for the next generation machines.

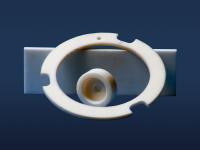

自華光電®表面黏著技術工具 myBlossom® SMT Tools

自華光電®表面貼裝技術

可提供各類傳統工藝條件下的表面貼裝技術工具和/或特製工藝條件下的表面貼裝技術工具,每一種具體需求均可獲得最佳工藝性能。MPP獨一無二的材料組合,有助於提高生產率,它的精確設計能夠:減少真空檢測誤差、減少部件損失率、良好的光學識別體系可用於無反射陶瓷,甚至可應用到金屬零件上。

將其自身定位為表面貼裝技術的領航者,因為:

在品質方面-可提供具有較高幾何準確度和重複率的產品,以滿足嚴格制定的半導體行業標準。在設計靈活性方面-具有按客戶要求設計製造幾何形狀的技術能力,可滿足多樣化的應用領域的挑戰。在材料方面 - 獨一無二的陶瓷刀片與各類材料組合在一起,應用廣泛。(如:塑膠、金屬),可改善工具性能,增加生產率。在 "性價比"方面提供最佳選擇—創新型的陶瓷噴嘴可增強產品壽命,讓產品價格具有競爭力。

myBlossom® SURFACE MOUNT TECHNOLOGY

Offers surface mount technology tools for conventional process and/or for customized process per specific applications. MPP delivers improved productivity due to a unique material combination and an accurate design enabling: Less vacuum detection errors、Reduced component drops、Better optical recognition with non-reflective ceramic and even with metal parts.

Positioned as the market leader for SMT tools due to:

myBlossom® SURFACE MOUNT TECHNOLOGY

Offers surface mount technology tools for conventional process and/or for customized process per specific applications. MPP delivers improved productivity due to a unique material combination and an accurate design enabling: Less vacuum detection errors、Reduced component drops、Better optical recognition with non-reflective ceramic and even with metal parts.

Positioned as the market leader for SMT tools due to:

Quality - high geometrical accuracy and repeatability which meet the strict standards of the semiconductor industry. Design flexibility and capabilities to meet diverse application challenges. Material – MPP's unique ceramic tip can be combined with a wide range of materials (i.e. plastic, metal) that improve tool performance and increase productivity. Best "value to price" ratio - innovative ceramic nozzle allows longer life span at a competitive price.

自華光電®球焊 myBlossom® Ball Soldering

自華光電®球焊

在此硬磁碟機(HDD)的裝配過程中可使用到各種類型的工具和材料:毛細管、劈刀、卷帶自動接合工具和點膠頭。目前,焊料射流鍵合工藝是一種標準技術,可支援硬碟驅動器。除了普通的硬碟驅動器應用領域以外,硬碟驅動器工藝還普遍應用于其他應用領域,例如:硬碟驅動器裝配(磁阻磁頭, HAS, 連接裝置)。球柵陣列封裝/塑膠無引線晶片載體的球焊技術。攝像機模組。晶圓滾筒打磨和晶片尺寸封裝過程中的錘擊工藝。

它具有領先的技術設計,經證明,它具備解決大尺寸、高精度、內表面粗糙、精確的內部幾何圖形的技術能力以及可提供具有競爭力的價格,這些都均使MPP在焊料射流工具製造方面成為技術領先的供應商。

myBlossom® BALL SOLDERING

The Hard Disk Drive (HDD) assembly process uses a variety of tool types and materials: Capillaries, Wedges, TAB Tools and Dispensers. Solder Jet Bonding (SJB) is now the standard technology to support HDD requirements. Beside the common HDD applications, the Solder Jet process is also common for the following applications: Hard Disk Drive Assembly (HGA, HAS, Hook-Up)、BGA / cLCC Balling、Camera Modules (VCM)、Wafer Bumbling and CSP Bumping.

Technological edge design and proven capability to handle high dimensional accuracy, inner surface roughness and accurate inner geometry, along with competitive pricing, make MPP the leading supplier for SJB tools.

Technological edge design and proven capability to handle high dimensional accuracy, inner surface roughness and accurate inner geometry, along with competitive pricing, make MPP the leading supplier for SJB tools.

自華光電®配件 myBlossom® Accessories

自華光電®配件

已研製出最先進的製造技術,可滿足多種行業應用領域的客戶需求,具體地說,MPP的工程部已經開發出半導體行業中所使用的特製配件:它採用前沿工藝、封裝裝配和表面貼裝技術工藝。

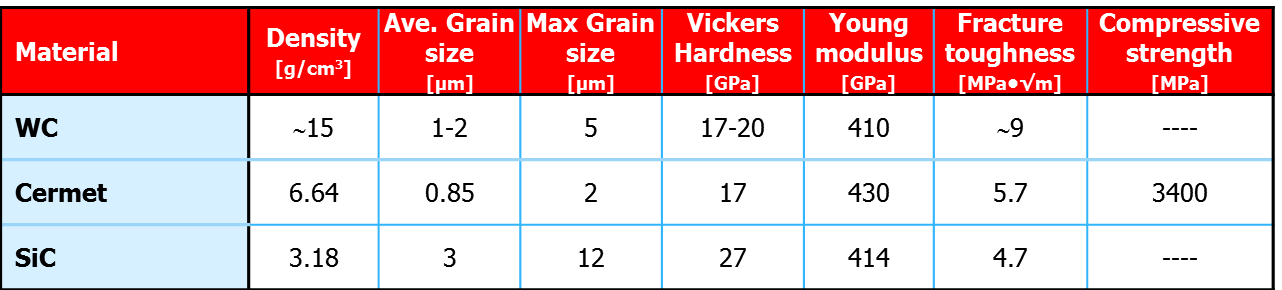

採用各種高端材料,例如:碳化鎢、經過熱處理的不銹鋼、碳化矽、碳化鈦、陶瓷、特種塑膠等等,使用這些材料可對於小規模與大規模生產中所使用的不同類型的配件設計提供支援。

myBlossom® ACCESSORIES

Has developed state-of-the-art manufacturing technologies which assist us in meeting customized requests in multiple industries. More specifically, MPP’s engineering department developed tailor-made accessories for the semiconductor industry including front end process, packaging assembly and SMT process.

The variety of high end materials such as Tungsten Carbide, Tempered Stainless Steel, Silicone Carbide, Titanium Carbide, Ceramics and Plastics, allows MPP to support these industries with a variety of accessories designed for small and large scale production.

The variety of high end materials such as Tungsten Carbide, Tempered Stainless Steel, Silicone Carbide, Titanium Carbide, Ceramics and Plastics, allows MPP to support these industries with a variety of accessories designed for small and large scale production.

自華光電®薄膜塗層 myBlossom® Thin Film Coatings

自華光電®薄膜塗層

專門研究使用最新的HVCS技術(高壓冷濺射)的薄玻璃防護塗料領域。這種在低溫和高壓下獨特且獲得專利的組合可在30°-150°C的低溫下運行,從而形成非晶薄膜。可以使用多種陶瓷和金屬塗層。 HV冷濺射是微電子,光學,醫療,航空航天,機械工具和精密機械中的首選塗層選擇。

優勢包括:

優勢包括:

提高耐磨性並延長粘合工具,切割和加工工具,齒輪,軸承和塑料模具的壽命。

提供防腐塗層,並在惡劣的環境條件下增強表面保護。

通常用於光學反射鏡(鋁和銀),粘合在一起的材料(複合材料,塑料,金屬),模具,閥門,加工的精密零件,模具處理工具,粘合和真空吸頭工具。

特性:

特性:

矽基

改善附著力

塗層厚度範圍為0.2-3 µ

低孔隙度

塗層材料:

塗層材料:

陶瓷:氧化鋁,二氧化矽,氧化鉻,氮化矽,氮化鋁,氧化鈦,碳化鎢等。

金屬:鉭,鈦,鎳,鉻,鋯,鈀,金和銀

myBlossom® THIN FILM COATINGS

myBlossom® THIN FILM COATINGS

Specializes in the field of thin protective glasslike coatings using state-of-the-art HVCS Technology (high voltage cold sputtering). Operating at low temperatures of 30°-150°C, this unique and patented combination of low temperature and high voltage creates an amorphous thin film. A variety of ceramic and metal coatings are available. HV Cold Sputtering is a preferred coating option for applications in microelectronics, optics, medical, aerospace, machining tools and precision mechanics.

Advantages include:

Advantages include:

Increases wear resistance and prolongs life span of bonding tools, cutting and machining tools, gears, bearings and plastic molds.

Provides anti-corrosive coating and increases surface protection in aggressive environmental conditions.

Commonly used on optical reflectors (aluminum & silver), materials glued together (composites, plastics, metals), molds, valves, machined precision parts, die handling tools, bonding and vacuum tip tools.

Properties:

Properties:

Silicon based

Improved adhesion

Coating thickness ranges from 0.2 - 3 µ

Low porosity levels

Coating Materials:

Coating Materials:

Ceramics: alumina, silica, chrome oxide, silicon nitride, aluminum nitride, titanium oxide, tungsten carbide and others.

Metals: tantalum, titanium, nickel, chrome, zirconium, palladium, gold and silver

自華光電®材料 myBlossom® Materials

Micro Point Pro Ltd. (MPP Tools)

Click here

材料

已開發出處理各種材料(包括金屬,塑料和復合材料)的技術能力。

我們的客戶受益於:

選擇最適合其應用的材料特性的能力

我們在模具和沖壓方面的廣泛知識

我們能夠製造複雜的設計和形狀以滿足獨特的應用和要求

我們的高端和定制機械可支持精確的生產和適應性,以滿足嚴格的公差要求

高重複性

使用的常用材料有:

1. 陶瓷材料

使用的常用材料有:

1. 陶瓷材料

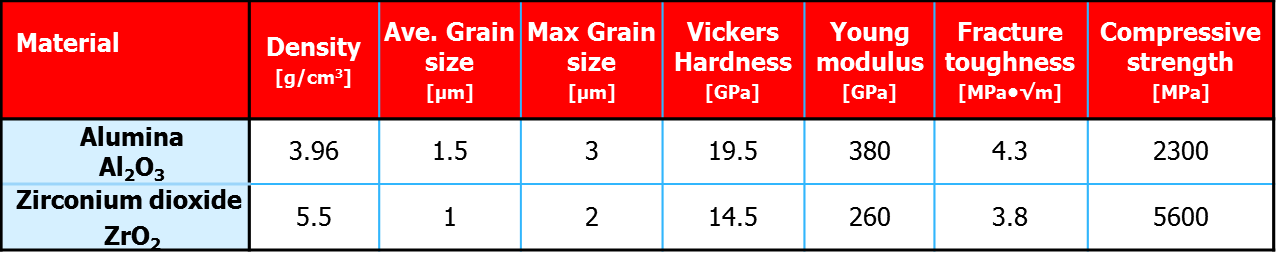

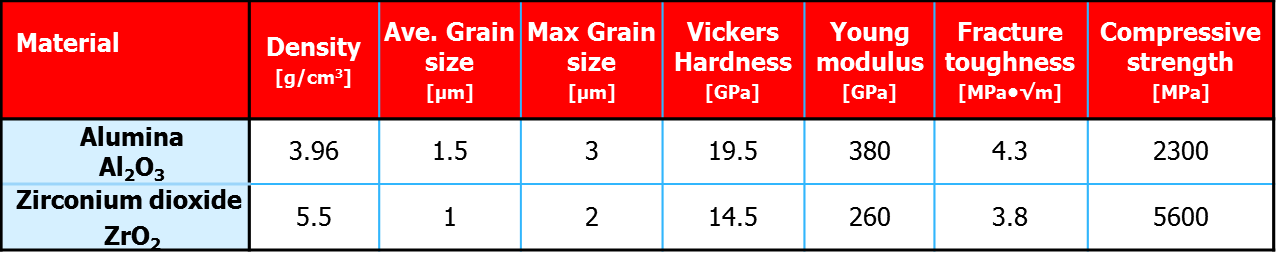

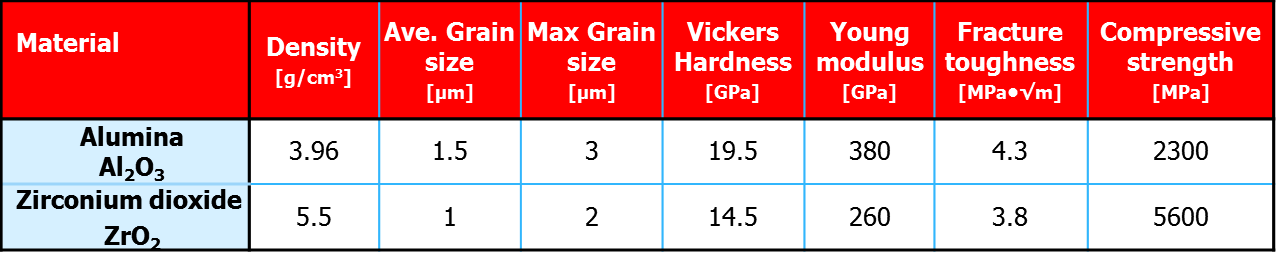

1.1 結構陶瓷:氧化鋁和氧化鋯

1.2 機械加工陶瓷– MACOR

1.2 機械加工陶瓷– MACOR

1.3 介電陶瓷–高K值,高達20,000

2. 金屬加工零件

2. 金屬加工零件

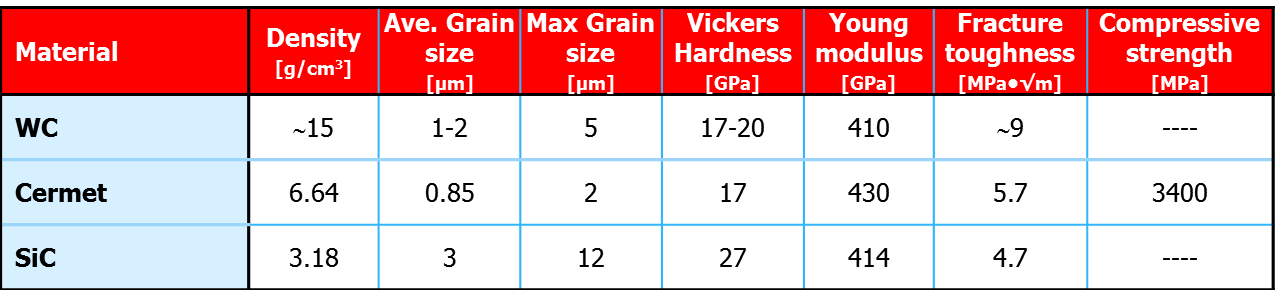

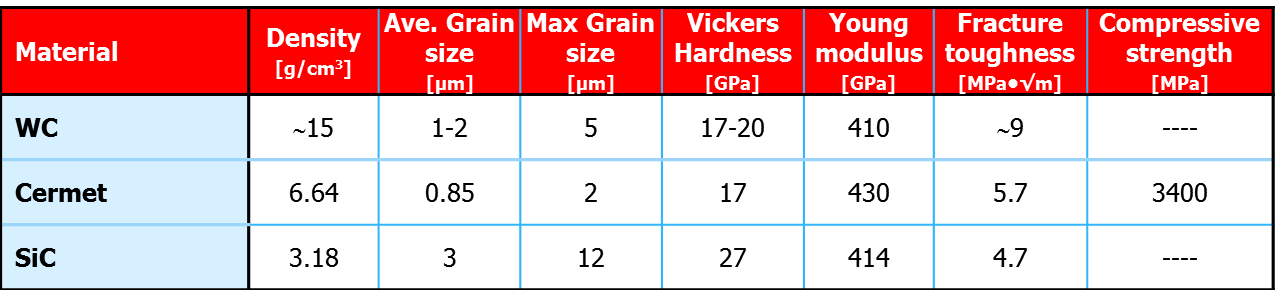

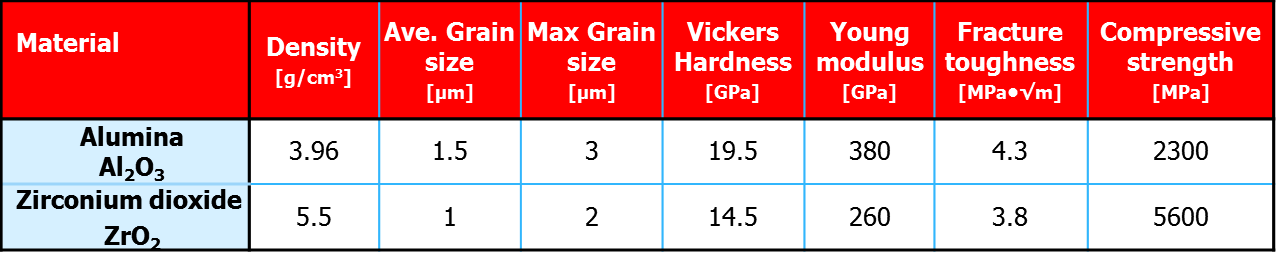

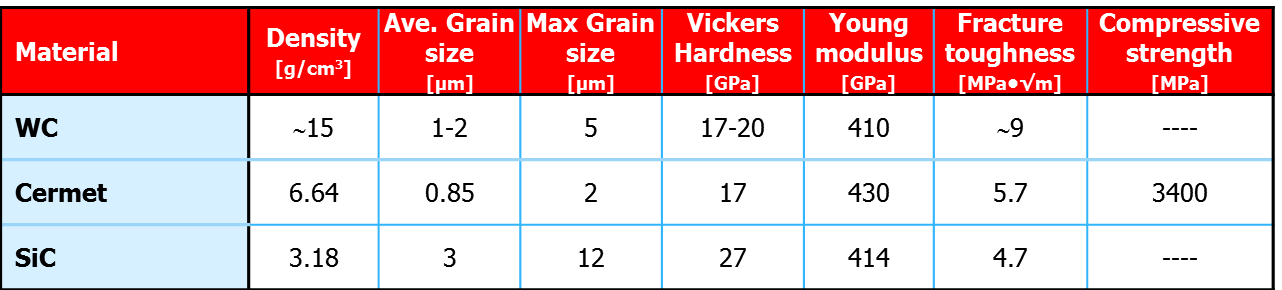

2.1 碳化物– WC,SiC,TiC(金屬陶瓷)

碳化鎢WC-用於工業機械,切削工具,磨料和裝甲

金屬陶瓷-用於耐磨零件,切削工具刀頭,金屬成型工具

SiC –具有高耐腐蝕性和良好的熱傳遞;適用於機械密封,耐磨零件和高溫環境中使用的零件

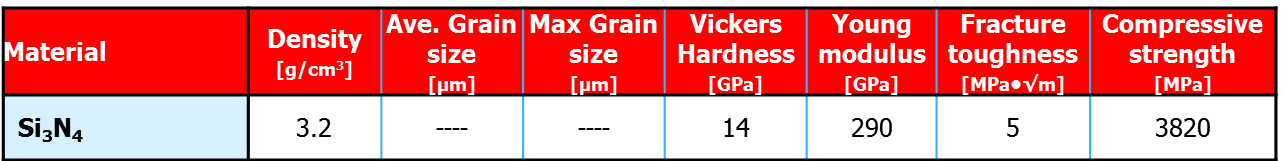

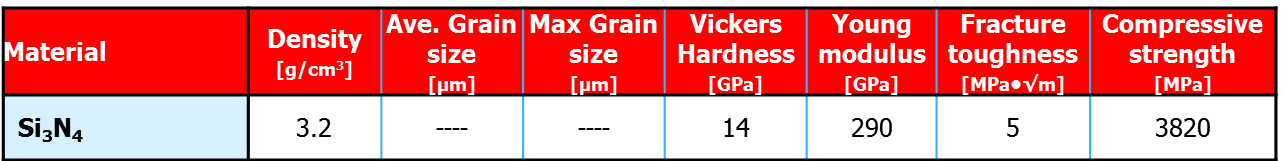

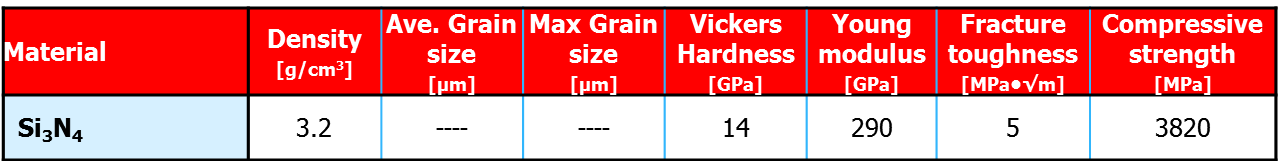

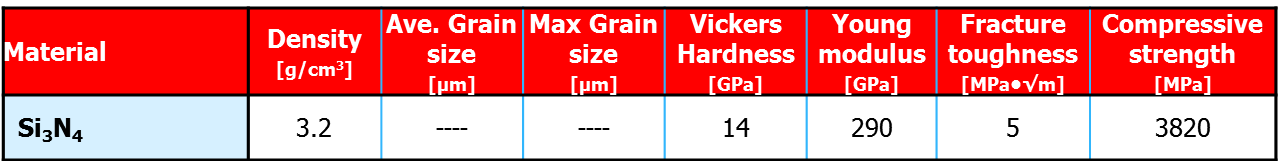

2.2 氮化物-SiN

2.2 氮化物-SiN

提供高耐熱衝擊性,適用於發動機零件,燃氣輪機零件和其他零件。

3. 塑料-PEEK,Vespel,PVC,Delrin,Torlon,W5000,

3. 塑料-PEEK,Vespel,PVC,Delrin,Torlon,W5000,

MPP的設備齊全,可以處理針對ESD特性,特殊硬化特性進行了調整的各種塑料材料,並且還可以處理高達450攝氏度的高溫工藝。

MATERIALS

Has developed technological capabilities to handle a variety of materials including metal, plastic and composites.

Our customers benefit from:

MATERIALS

Has developed technological capabilities to handle a variety of materials including metal, plastic and composites.

Our customers benefit from:

The ability to select the most suitable material properties for their application

Our extensive knowledge in molds and pressing

Our ability to manufacutre complex designs and shapes to meet unique applications and requirements

Our hi-end and custom made machinery which supports precise production and abiity to meet tight tolerances

High degree of repeatability

Common materials used are:

1. Ceramic Materials

Common materials used are:

1. Ceramic Materials

1.1 Structural Ceramics: Alumina & Zirconia

1.2 Machine able Ceramic – MACOR

1.2 Machine able Ceramic – MACOR

1.3 Dielectric Ceramic – High K value, up to 20,000

2. Metallic Machined Parts

2. Metallic Machined Parts

2.1 Carbide – WC, SiC, TiC (cermet)

WC, Tungsten Carbide - used in industrial machinery, cutting tools, abrasives, and armor

Cermet - used for wear-resistant parts, cutting tool tips, metal forming tools

SiC – Provides high corrosion resistance and good heat transfer; suitable for mechanical seals, wear- resistant parts and parts used in high-temperature environments

2.2 Nitride – SiN

2.2 Nitride – SiN

Provides resistance to high thermal shock, suitable for engine parts, gas turbine parts and others.

3. Plastics – PEEK, Vespel, PVC, Delrin, Torlon,W5000,

3. Plastics – PEEK, Vespel, PVC, Delrin, Torlon,W5000,

MPP is well equipped to handle a variety of plastic materials that are adjusted for ESD characteristics, special hardening characteristics, and also capable to handle high temp process up to 450 deg C.

自華光電®楔焊|球焊線機(手動) myBlossom® iBond5000-Dual Wire Bonder

自華光電® iBond5000多功能鍵合機 / 楔焊|球焊線機(手動) / 楔焊|球焊打線機(手動)

iBond 5000多功能鍵合機集成了4500手動鍵合機的機械設計原理與先進的圖形化使用者介面。

iBond 5000多功能鍵合機可以處理球焊,搪焊工藝。iBond 5000是一台先進的球焊/楔焊一體機,可以為工藝研發,生產製造提供有力的技術支援。

iBond 5000功能多樣,可創造出業界的最佳價值,支援混合電路,MCM多晶片模組﹑光學器件﹑微波器件﹑感測器﹑大功率產品﹑雷射器件及分立器件等多種產品應用。

myBlossom® iBond5000-DUAL WIRE BONDER

The iBond5000 Series integrates the proven 4500 manual wire bonder mechanical design with an advanced graphical user interface. The iBond5000 Series includes 3 basic models: Wedge, Ball and Dual. The iBond5000-Dual is an advanced ball/wedge bonder used for process development, production, research or added manufacturing support. The iBond5000 provides the high yield and excellent repeatability needed for every wedge bonding application including: Optoelectronic Modules, Hybrids/MCMs, Microwave Products, Discrete Devices/Lasers, Chip-on-Boards, Leads, Sensors, High Power Devices and much more.

自華光電®楔焊線機|球焊線機

Allen K. Lin | Allen@myblossom.tw | LINE ID: Allen-007 | Wechat ID: Allen-006 | T: 0910-782775

Allen K. Lin | Allen@myblossom.tw | LINE ID: Allen-007 | Wechat ID: Allen-006 | T: 0910-782775

自華光電®楔焊線機(手動) myBlossom® iBond5000-Wedge Wire Bonder

自華光電® iBond5000楔焊鍵合機 / 楔焊線機(手動) / 楔焊打線機(手動)

iBond5000楔焊鍵合機將4500手動鍵合機的機械設計原理與先進的圖形化使用者介面進行了良好的集成優化;可以為工藝研發,生產製造提供有力的技術支援。

iBond5000楔焊鍵合機功能多樣,可創造出業界的最佳價值,支援混合電路, MCM多晶片模組﹑ 光學器件﹑微波器件﹑感測器﹑大功率產品﹑雷射器件及分立器件等多種產品應用。

myBlossom® iBond5000-WEDGE WIRE BONDER

The iBond5000 Series integrates the proven 4500 manual wire bonder mechanical design with an advanced graphical user interface. The iBond5000 Series includes 3 basic models: Wedge, Ball and Dual.

The iBond5000-Wedge is an advanced wedge bonder used for process development, production, research or added manufacturing support. The iBond5000 provides the high yield and excellent repeatability needed for every wedge bonding application including: Optoelectronic Modules, Hybrids/MCMs, Microwave Products, Discrete Devices/Lasers, Chip-on-Boards, Leads, Sensors, High Power Devices and much more.

自華光電®球焊線機(手動) myBlossom® iBond5000-Ball Wire Bonder

自華光電® iBond5000球焊鍵合機 / 球焊線機(手動) / 球焊打線機(手動)

iBond5000 球焊鍵合機將4500手動鍵合機的機械設計原理與先進的圖形化使用者介面進行了良好的集成優化;可以為工藝研發,生產製造提供有力的技術支援。

iBond5000 球焊鍵合機功能多樣,可創造出業界的最佳價值,支援混合電路, MCM多晶片模組﹑ 光學器件﹑微波器件﹑感測器﹑大功率產品﹑雷射器件及分立器件等多種產品應用。

myBlossom® iBond5000-BALL WIRE BONDER

The iBond5000 Series integrates the 4500 manual wire bonder mechanical design with an advanced graphical user interface. The iBond5000 Series includes 3 basic models: Wedge, Ball and Dual.

The iBond5000-Ball is an advanced ball bonder used for process development production, research or added manufacturing support. The iBond5000 provides the high yield and excellent repeatability needed for every gold ball bonding application including: Optoelectronic Modules, Hybrids/MCMs, Microwave Products, Discrete Devices/Lasers and much more.

自華光電®手動楔焊線機工作臺 myBlossom® Manual Wire Bonder Workholders

自華光電®手動楔焊機工作臺

MPP 針對不同的手動機產品應用推出了一系列的工作臺, 可處理標準產品和定制產品。

產品手冊系列中的工作臺可匹配任何一台MPP手動機使用,更多的工作臺產品將陸續推出。

MPP手動機部門將開發更多先進的工作臺產品以滿足未來日益更新的產品需求。

myBlossom® MANUAL WIRE BONDER WORKHOLDERS

MPP introduces its Workholder Catalog for Manual Wire Bonder Applications.

This catalog offers our wide range of workholders for standard and customized applications, suitable for use with all types of manual bonders.

The MPP Manual Bonder Division continues to develop advanced workholders designed to fit your specific application challenges and needs.

The MPP Manual Bonder Division continues to develop advanced workholders designed to fit your specific application challenges and needs.

2019年全球焊針市場規模

QY Research

Click here

2019年全球焊針/瓷嘴市場規模、見解、需求 & 2024年預測

Global Bonding Capillaries Market 2019 Size, Insights, Demand and Forecast 2024

Published by: QY Research | On: Mar 2019

Global Bonding Capillaries Market: Overview

Get a complete insight into the worldwide Bonding Capillaries Industry in this Global Bonding Capillaries Market Report. Starting from Monetary Contribution, Impact on the Economy, Types of Product/service, Key players, Previous five years of history (2014-2018), Evaluate the market size in terms of sales (volume and value) and Market Forecast by Regions, Type and Application (2019-2026).

Rapidly changing lifestyles and urbanization has lead to an increase in the growth of the global Bonding Capillaries market. With different substantial advancements made related to Bonding Capillaries, the Bonding Capillaries global market is are probably going to be increasing with the help of the various frameworks. Furthermore, the expanding population over the world significantly going to move the development of the Bonding Capillaries market on a worldwide scale.

Global Bonding Capillaries Market: Key Players

These key players have single-handedly acquired the market utilizing various strategies and continue to do so in the upcoming years. According to QYMarketStudy competitive players the consumption and demand in the global Bonding Capillaries market have increased, and they believe it shows a good growth compared to the past years in the future.

The key players/manufacturers covered in this report with sales, revenue, market share for each company:

SPT Group, Small Precision Tools, Inc. (Switzerland)

K&S Bonding Tools (Singapore)

Gaiser Tool Company (U.S.)

Adamant Co., Ltd. (Japan)

H. Fillunger & Co. Pvt. Ltd. (India)